Remanufacture a Slewing ring bearings : Up to 70% Savings and Expedited Component Delivery

If you’re involved in manufacturing or industrial machinery maintenance, you’re likely aware of the importance of reducing maintenance costs without compromising quality and efficiency. Remanufacture Slewing ring bearings emerges as an advantageous solution, allowing for significant savings of up to 70% compared to replacing new components, accompanied by quick delivery times to ensure a prompt return to normal operations. In this article, we’ll explore the process of regenerating slewing ring bearings , highlighting the benefits and illustrating how this practice can improve profitability and reliability in industrial activities.

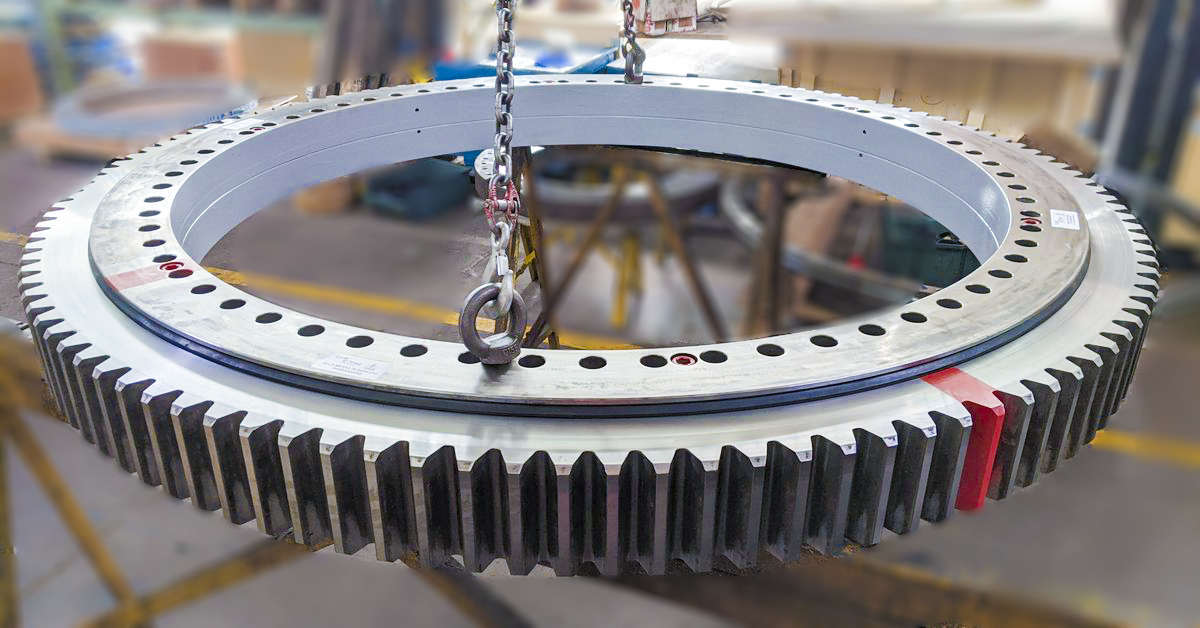

What Does Remanufacture a Slewing ring bearings Mean?

A process through which worn-out mechanical components are repaired and restored to their optimal performance, without the need for replacing them with new parts. This process involves several steps, including inspection, cleaning, replacement of damaged parts, and lubrication, to restore the functionality and reliability of the rotation bearing.

Benefits of Remanufacture Slewing ring bearings

- Economic Savings: Remanufacture offers significant savings compared to purchasing new components, allowing companies to reduce maintenance costs and invest resources in other critical areas of the business.

- Reduced Machine Downtime: Thanks to the expedited delivery of the regenerated component, companies can minimize machine downtime, thereby maintaining high productivity and limiting production losses.

- Environmental Sustainability: Remanufacture slewing ring bearings instead of replacing them with new components contributes to waste reduction and extends the useful life of mechanical devices, promoting environmental sustainability.

- Guaranteed Quality: Despite the lower cost, regenerated components undergo rigorous quality controls to ensure reliable performance and compliance with industrial standards.

Process of Remanufacture

The process of remanufacture follows a series of well-defined phases:

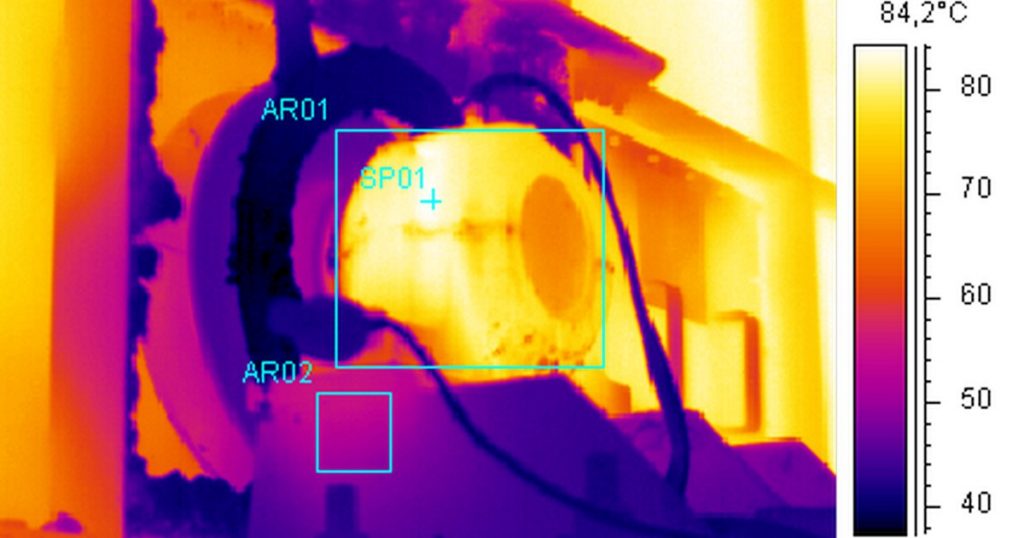

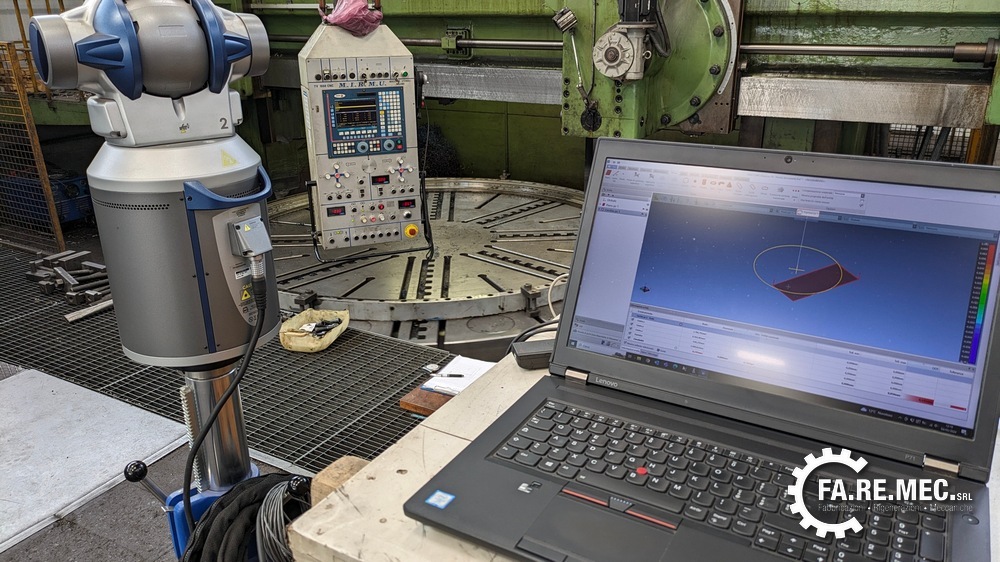

- Initial Inspection: A detailed inspection of the component is carried out to identify damages and areas requiring intervention.

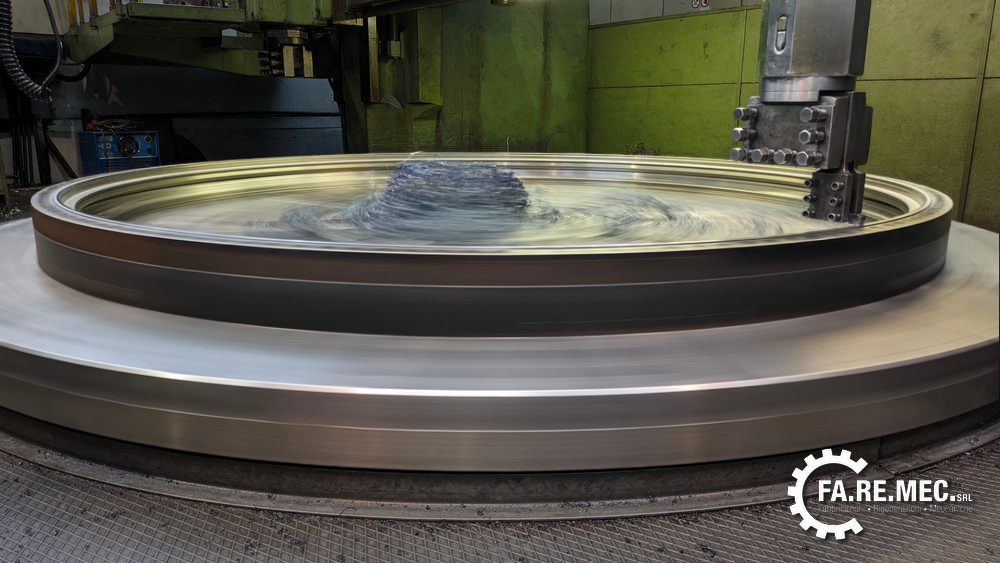

- Disassembly and Cleaning: The rotation bearing is disassembled and thoroughly cleaned to remove residues and impurities.

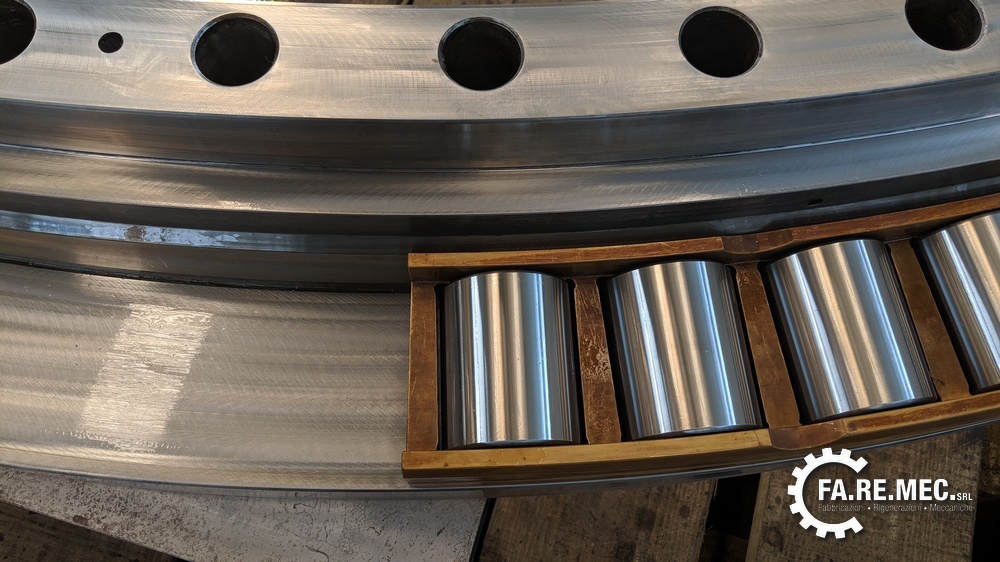

- Replacement of Damaged Parts: Damaged parts are replaced with high-quality components to restore the original performance.

- Assembly and Lubrication: The component is then assembled and properly lubricated to ensure smooth and reliable operation.

- Quality Testing: Finally, the regenerated component undergoes quality testing to verify performance and durability.

In conclusion, the remanufacturing of slewing rings offers a significant opportunity for companies to reduce maintenance costs, minimize machine downtime and improve environmental sustainability.

Contact us to benefit from the economic and practical advantages of how we remanufacture slewing rings.

Versione Italiana

Versione Italiana